Two exhibited products were well received.

The 8th China CNC Machine Tool Exhibition closed on February 28. Our company adhering to the purpose of innovation and development, and launched two new products. That is JCB20MP NC arc gear grinding machine and JCB12 NC arc gear milling machine, which are well received by users.

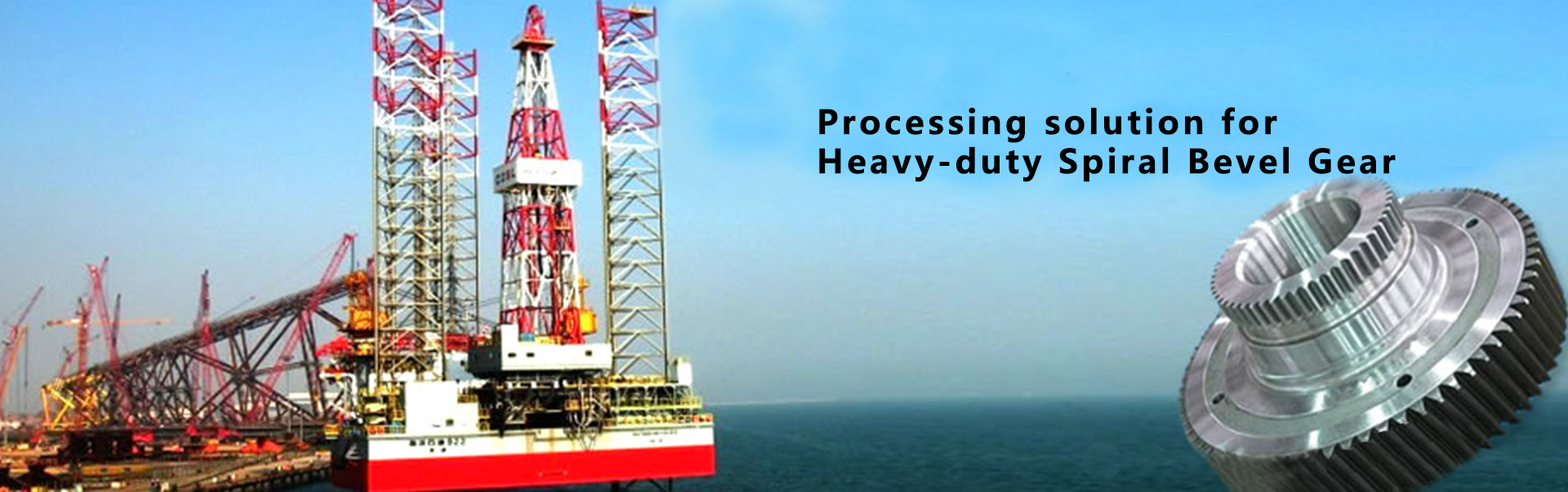

JCB20MP spiral umbrella gear milling machine is developed under the background of the continuous improvement of manufacturing level in our country. Six axes and five linkages of Siemens 840D system are adopted, and the B axis linkage is added, so the tool tilting process can be realized, the torque motor and the spindle direct drive can be realized, which ensures the working accuracy and the rigidity of the machine tool, and the closed and semi-closed CNC system can be realized. Ring control improves the accuracy. CNC dresser roller speed direction is adjusted freely to ensure the correction accuracy. It is mainly used for small modulus gear milling machine with cutting modulus less than 4M pitch diameter less than 200, and its precision reaches P5 level in China. This type of machine tool is the first one in China. As you know, the requirements for machine tool design and processing technology of small modulus gear milling machine are higher. Especially, the matching of small grinding wheel and workpiece is more complicated than that of big gear. Our company has overcome the difficulties of small die grinding machine and filled a domestic gap. It provides high-efficiency and high-quality equipment for middle and high-end enterprises.

JCB12 NC spiral bevel gear milling machine is another highlight of this exhibition. The product developed by our company is a brand-new concept, a brand-new structure of machine tools, from the first generation of fixed machine tools center, the second generation of virtual machine tools center to the third generation of dynamic virtual center processing machine tools.

The machine adopts the internationally popular dry cutting technology, and its processing efficiency is twice as high as that of wet cutting. While improving efficiency, the cost of cooling oil and water is saved, and the equipment management is simpler. The machine is equipped with automatic feeding and unloading device to further improve the production efficiency. In theory, it has jumped from 6 machine tools operated by one person to 20 machine tools operated by one person. It can be seen that the performance-price ratio of the machine is above average.

The above two kinds of machine tools have attracted great attention from users at the exhibition. Many new and old users have heard from them, and users have ordered machine tools on the spot.

086-022-24981179

086-022-24981179